Han Yongming,Associate Professor,Master's Supervisor

Graduated from Beijing University of Chemical Technology with a PhD in Control Theory and Control Engineering in June 2014 and stayed on as a teacher. At the same time, he joined the School of Chemical Engineering as a postdoctoral fellow. In June 2016, he left the station as a youth reserve of Beijing University of Chemical Technology. Introduce talents and stay in the school to teach. In May 2017, he was selected as a member of Beijing University of Chemical Technology Young Talents Hundred Talents Program. He is currently a member of the Chinese Society of Automation, a professional member of the Chinese Society of Chemical Industry and a member of the Beijing Society of Automation. Research fields include system modeling and optimization, energy efficiency evaluation, data ****ysis and information integration, and intelligent optimization methods. In the past five years, as the first author/correspondence contact, published more than 70 academic papers (over 60 in SCI/EI: total impact factor 214.278, 18 papers in the first district of Chinese Academy of Sciences/JCR, 20 papers in the second district (top 33, ESI) 3 high-cited papers, 1 high-cited paper from China Chemical Industry Society 2014-2018), authorized 5 invention patents, applied for 20 patents, presided over the National Natural Science Foundation of China, Youth Project and Beijing Excellent Talents Training Funding Program, Participated in more than ten projects such as the National Key Research and Development Program and the National Natural Science Foundation of China. Received the 2020-2022 Youth Talent Promotion Program of the Beijing Association for Science and Technology, the 2019 Energy and Built Environment Young Academic Newcomer Nomination Award, Beijing 2018 Young Technological Innovative Talent Award from the Society of Automation, etc.

Research Projects

project name | project source |

Research on Key Technologies of Energy System Modeling and Optimization for Complex Petrochemical Process | National Natural Science Foundation of China, Youth Project |

Research on Energy Efficiency Analysis and Prediction Method of Complex Chemical Process Based on DEA | National Natural Science Foundation of China, Youth Project |

Research and Application of Multi-level Evaluation Method for Energy Efficiency in Complex Petrochemical Industry | Beijing Excellent Talents Training Funding Program Project |

Multi-level energy efficiency evaluation and resource allocation for large buildings | Beijing Association for Science and Technology Golden Bridge Project Seed Fund C project |

Research Paper

[1] Geng, Z., Zhang, Y., Li, C., Han, Y.*, Cui, Y., & Yu, B. Energy optimization and prediction modeling of petrochemical industries: An improved convolutional neural network based on cross-feature. Energy, 2020, 194: 116851.

[2] Zhiqiang Geng , Ning Chen, Yongming Han ∗, Bo Ma*. An improved intelligent early warning method based on MWSPCA and its application in complex chemical processes. The Canadian Journal of Chemical Engineering.

[3] Yongming Han, Rundong Zhou , Zhiqiang Geng* , Ju Bai , Bo Ma *, Jinzhen Fan. A novel data envelopment ****ysis cross-model integrating interpretative structural model and ****ytic hierarchy process for energy efficiency evaluation and optimization modeling: Application to Ethylene Industries。Journal of Cleaner Production 246 (2020): 118965

[4] Yongming Han, Shuheng Zhang, Zhiqiang Geng*, Qin Wei, Zhi Ouyang. Level Set based Shape Prior and Deep Learning for Image Segmentation[J]. IET Image Processing. 2020, 14(1): 183-191.

[5] Zhiqiang Geng , Guofei Chen, Yongming Han ∗, Fang Li, Gang Lu, Qing Wei*. Semantic relation extraction using sequential and tree-structured LSTM with attention. Information Sciences 509 (2020) 183–192 .

[6] Bo Ma#, Yongming Han#,*, Shiying Cui, Zhiqiang Geng*, Hongda Li, Chong Chu. Risk early warning and control of food safety based on an improved ****ytic hierarchy process integrating quality control ****ysis method. Food Control. 108(2020), 106824.

[7] Yongming Han, Chenyu Fan, Meng Xu, Zhiqiang Geng*, Yanhua Zhong. Production capacity ****ysis and energy saving of complex chemical processes using LSTM based on attention mechani**. Applied Thermal Engineering. 2019, 160, 114072.

[8] Yunfei Cui#, Yongming Han#, Zhiqiang Geng*; Qunxiong Zhu*, Jinzhen Fan, Production Optimization and Energy Saving of Complex Chemical Processes using Novel Competing Evolutionary Membrane Algorithm: Emphasis on Ethylene Cracking. Energy Conversion and Management, 196 (2019) 311–319.

[9] Yongming Han, Shiying Cui, Zhiqiang Geng*, Chong Chu, Kai chen, Yajie Wang. Food quality and safety risk asses**ent using a novel HMM method based on GRA. Food Control 105 (2019) 180–189

[10] Zhiqiang Geng, Rongfu Zeng, Yongming Han *, Yanhua Zhong, Hua Fu. Energy efficiency evaluation and energy saving based on DEA integrated affinity propagation clustering: Case study of complex petrochemical industries. Energy, 2019,179: 863-875.

[11] Yongming Han, Chang Long, Zhiqiang Geng*, Qunxiong Zhu*, Yanhua Zhong. A novel DEACM integrating Affinity Propagation for performance evaluation and energy optimization modeling: Application to complex petrochemical. Energy Conversion and Management, 2019 ,183 , 349–359.

[12] Zhiqiang Geng , Qingchao Meng, Ju Bai, Jie Chen, Yongming Han ∗, Qing Wei*, Zhi Ouyang. A model-free Bayesian classifier. Information Sciences 482(2019) 171–188 .

[13] Xiaoyong Lin, Shiying Cui, Yongming Han*, ZhiqiangGeng*, Yanhua Zhong. An improved ISM method based on GRA for hierarchical ****yzing the influencing factors of food safety. Food Control.2019, 99: 48-56

[14] Yongming Han, Hao Wu, Minghui Jia, Zhiqiang Geng*, Yanhua Zhong. Production capacity ****ysis and energy optimization of complex petrochemical industries using novel extreme learning machine integrating affinity propagations. Energy Conversion and Management, 2019, 99, 48–56.

[15] ZhiqiangGeng, Dirui Shang, Yongming Han*,Yanhua Zhong. Early warning modeling and ****ysis based on a deep radial basis function neural network integrating an ****ytic hierarchy process: A case study for food safety. Food Control.2019,96:329-342

[16] ZhiqiangGeng, Xuan Hu, Yongming Han*, Yanhua Zhong, A novel leakage detection method based on the sensitivity matrix of the pipe flow: Case study of water distribution systems. Journal of Water Resources Planning and Management. 2019, 145(2): 04018094-1-12

[17] ZhiqiangGeng, Xuan Hu, Ning Ding, Shanshan Zhao, Yongming Han*.A pattern recognition modeling approach based on the intelligent ensemble classifier:Application to identification and appraisal of water-flooded layers. Part I-Journal of Systems and Control Engineering. 2019, 233(7):737-750.

[18] ZhiqiangGeng, Zun Wang, Haixia Hu, Yongming Han*, Xiaoyong Lin*. A Fault Detection Method based on Horizontal Visibility Graph-Integrated Complex Networks: Application to Complex Chemical Processes. Canadian Journal of Chemical Engineering.2019:97(5):1129-1138.

[19] Yuan Xu, Mingqing Zhang, Liangliang Ye, Qunxiong Zhu , Zhiqiang Geng, Yan-Lin He, YongmingHan*. A novel prediction intervals method integrating an error & selffeedback extreme learning machine with particle swarm optimization for energy consumption robust prediction. Energy, 164 (2018) 137-146.

[20] ZhiqiangGeng,HongdaLi,QunxiongZhu,YongmingHan*. Production prediction and energy-saving model based on Extreme Learning Machine integrated ISM-AHP: Application in complex chemical processes . Energy, 2018, 160: 898-909.

[21] Zhiqiang Geng, Ju Bai, Deyang Jiang, Yongming Han*.Energy structure ****ysis and energy saving of complex chemical industries:A novel fuzzy interpretative structural model. Applied Thermal Engineering 142 (2018) 433–443.

[22] Yongming Han, Qing Zeng, Zhiqiang Geng*, Qunxiong Zhu*. Energy management and optimization modeling based on a novel fuzzy extreme learning machine: Case study of complex petrochemical industries. Energy Conversion and Management, 2018, 145, 41–52.

[23] Yongming Han, Chang Long, Zhiqiang Geng*, Keyu Zhang*. Carbon emission ****ysis and evaluation of industrial departments in China: An improved environmental DEA cross model based on information entropy[J]. Journal of Environmental Management, 2018, 205: 298-307.

[24] Zhiqiang Geng, Yanan Li, Yongming Han*, Qunxiong Zhu*. A Novel Self-Organizing Cosine Similarity Learning Network: An Application to Production Prediction of Petrochemical Systems. Energy, 2018, 142: 400-410.

[25] Zhiqiang Geng , Zhongkun Li , Yongming Han ∗. A new deep belief network based on RBM with glial chains. Information Sciences 463–464 (2018) 294–306 .

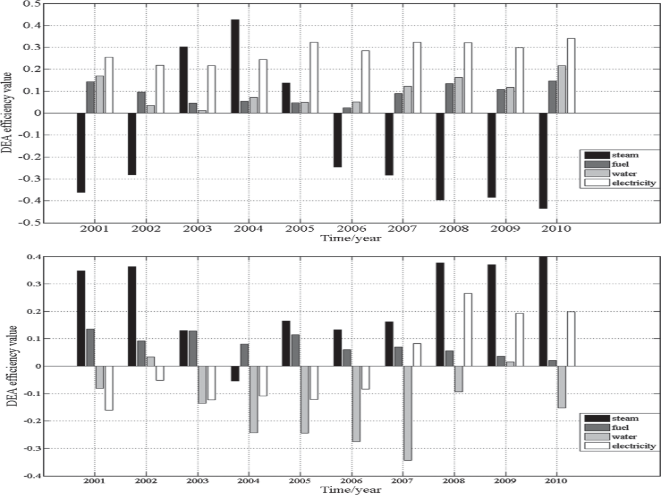

[26] Zhiqiang Geng, Jungen Dong, Yongming Han*, Qunxiong Zhu*. Energy and environment efficiency ****ysis based on an improved environment DEA cross-model: Case study of complex chemical processes. Applied Energy, 2017, 205, 465-476.

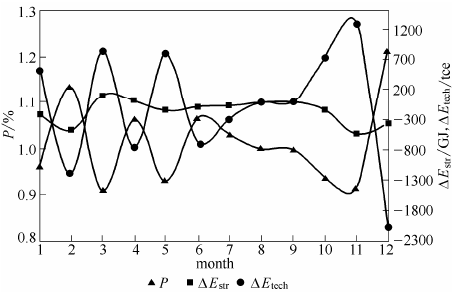

[27] Zhiqiang Geng, Huachao Gao, Yanqing Wang, Yongming Han*, Qunxiong Zhu*. Energy saving ****ysis and management modeling based on index decomposition ****ysis integrated energy saving potential method: Application to complex chemical processes. Energy Conversion and Management, 2017, 145, 41–52.

[28] Yunfei Cui, Zhiqiang Geng*, Qunxiong Zhu. Yongming Han*. Review: Multi-objective optimization methods and application in energy saving. Energy 2017, 125, 681-704

[29] Zhiqiang Geng, Xiao Yang, Yongming Han*, Qunxiong Zhu*. Energy optimization and ****ysis modeling based on extreme learning machine integrated index decomposition ****ysis: Application to complex chemical processes. Energy 2017,120, 67-78

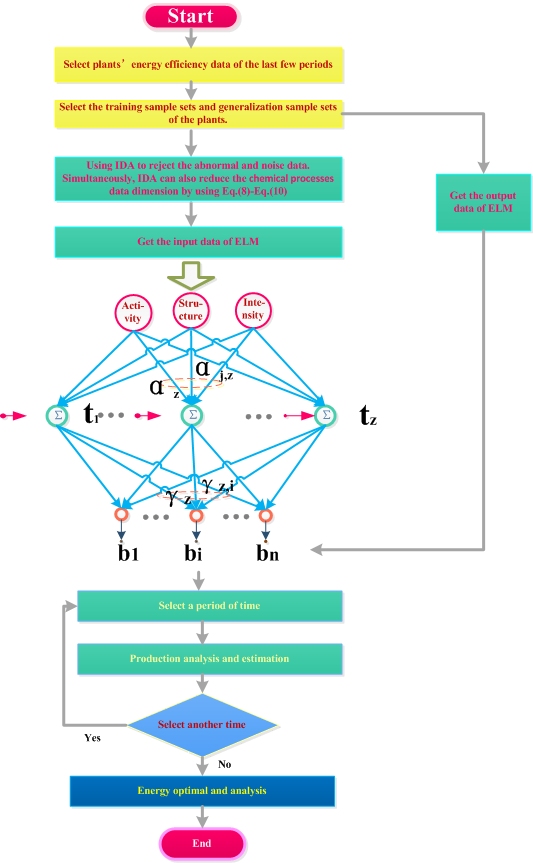

[30] Zhiqiang Geng, Lin Qin, Yongming Han*, Qunxiong Zhu*. Energy saving and prediction modeling of petrochemical industries: A novel ELM based on FAHP. Energy 2017,122, 350-362 (TOP/SCI)

[31] Yongming Han, Qunxiong Zhu, Zhiqiang Geng*, Yuan Xu*. Energy and carbon emissions ****ysis and prediction of complex petrochemical systems based on an improved extreme learning machine integrated interpretative structural model. Applied Thermal Engineering. 2017, 115, 280-291.

[32] Yongming Han, Zhiqiang Geng*, Yixin Qu, Qunxiong Zhu*. Linear optimization fusion model based on fuzzy C-means: Case study of energy efficiency evaluation in ethylene product. Journal of Analytical and Applied Pyrolysis 2017,125, 347–355

[33] Yaxun Chen, Yongming Han*, Qunxiong Zhu*. Energy and environmental efficiency evaluation based on a novel data envelopment ****ysis: An application in petrochemical industries. Applied Thermal Engineering. 2017, 119, 156-164.

[34] Zhiqiang Geng, Shanshan Zhao, Guangcan Tao, Yongming Han*. Early warning modeling and ****ysis based on ****ytic hierarchy process integrated extreme learning machine (AHP-ELM): Application to food safety. Food Control 2017, 78, 33-42.

[35] Zhiqiang Geng, Jungen Dong, Jie Chen, Yongming Han*. A new Self-Organizing Extreme Learning Machine soft sensor model and its applications in complicated chemical processes. A new Self-Organizing Extreme Learning Machine soft sensor model and its applications in complicated chemical processes. Engineering Applications of Artificial Intelligence. 2017, 62, 38-50.

[36] Zhiqiang Geng, Jie Chen, Yongming Han*. Energy Efficiency Prediction Based on PCA-FRBF Model: A Case Study of Ethylene Industries. IEEE Transactions on Systems Man Cybernetics-Systems. 2017, 47(8),1763-1773.

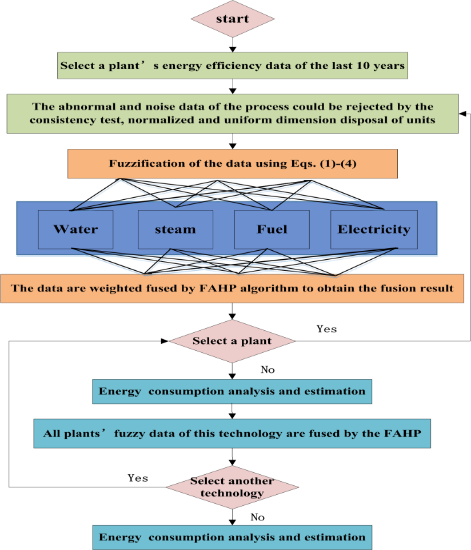

[37] Yongming Han, Zhiqiang Geng*, Qunxiong Zhu, Zun Wang, Yunfei Cui. Energy consumption ****ysis and evaluation of petrochemical industries using an improved fuzzy ****ytic hierarchy process approach. Journal of Intelligent & Fuzzy Systems. 2017,32(6),4183-4195.

[38] Zhiqiang Geng, Zun Wang, Chenglong Peng, Yongming Han*. A New Fuzzy Process Capability Estimation Method Based on Kernel Function and FAHP. IEEE Transactions on Engineering Management, 2016, 63(2): 177-188.

[39] Yongming Han, Zhiqiang Geng*, Zun Wang, Peng Mu. Performance ****ysis and optimal temperature selection of ethylene cracking furnaces: A data envelopment ****ysis cross-model integrated ****ytic hierarchy process. Journal of Analytical and Applied Pyrolysis 2016,122, 35–44

[40] Zhiqiang Geng, Zun Wang, Qunxiong Zhu, Yongming Han*. Multi-objective operation optimization of ethylene cracking furnace based on AMOPSO algorithm. Chemical Engineering Science. 2016,153, 21–33

[41] Yongming Han, Zhiqiang Geng *, Qunxiong, Zhu*. Energy optimization and prediction of complex petrochemical industries using an improved artificial neural network approach integrating data envelopment ****ysis. Energy Conversion and Management 2016,124, 73–83

[42] Yongming Han, Zhiqiang Geng*, Qunxiong Zhu*, Yixin Qu. Energy efficiency ****ysis method based on fuzzy DEA cross-model for ethylene production systems in chemical industry. Energy. 2015, 83, 685-695.

[43] Yongming Han, Zhiqiang Geng*, Xiangbai Gu*, Zun Wang. Performance Analysis of China Ethylene Plants by Measuring Malmquist Production Efficiency Based on an Improved Data Envelopment Analysis Cross-Model. Industrial & Engineering Chemistry Research 2015,54, 272-284.

[44] Yongming Han, Zhiqiang Geng*, Xiangbai Gu, Qunxiong Zhu*. Energy Efficiency Analysis based on DEA Integrated ISM: A Case Study for Chinese Ethylene Industries. Engineering Applications of Artificial Intelligence. 2015, 45, 80-89.

[45] Yongming Han, Zhiqiang Geng*, Qunxiong Zhu, Xiaoyong Lin. Energy consumption hierarchical ****ysis based on interpretative structural model for ethylene production. Chinese Journal of Chemical Engineering, 2015, 23(12): 2029-2036.

[46] Yongming Han, Zhiqiang Geng*. Energy Efficiency Hierarchy Evaluation based on Data envelopment ****ysis and its application in Petrochemical Process. Chemical Engineering & Technology, 2014, 37(12), 2085–2095

[47] Yongming Han, Zhiqiang Geng*, Qiyu Liu. Energy Efficiency Evaluation Based on Data Envelopment Analysis Integrated Analytic Hierarchy Process in Ethylene Production. Chinese Journal of Chemical Engineering 2014, 22(12), 1279-1284

Scientific research results

Aiming at the problems of energy saving and environmental emission reduction in the complex petrochemical process, a data fusion-based energy efficiency evaluation and energy saving potential ****ysis method for the entire chemical production process is proposed.

(1)Aiming at the energy consumption characteristics of the petrochemical process, a whole-process energy efficiency evaluation based on data fusion and a multi-level energy efficiency index extraction method were proposed, and a multi-level energy efficiency index system for the petrochemical process was established.

(2)Aiming at the comprehensive input and output data of the petrochemical process, a data envelopment ****ysis (DEA)-based evaluation method for the energy and environmental emission efficiency of the chemical process is proposed.